A website dedicated to educating users and the public about the dangers and requirements for safe laser machinery in europe.

Laser Safety,

Why Bother?

We only have two eyes!

A split second of stray laser light is all that is required to irreversibly damage your vision.

With the explosion of desktop laser cutters, aimed at schools, business and hobbyists, it is important to enable users to make informed decisions about the machines they are purchasing. Many are unaware of the potential life altering risk. Bad manufactures typically mislabeling and not conforming with the essential health and safety directives.

Any Machinery sold in the EU must comply with the Machinery directive. Next to the directives there are Harmonised standards which guide a manufacturer on how to build a laser safe machine.

Additionally there is a legally binding European Commission Decision on the safety requirements to be met by European standards for consumer laser products, which states that any consumer laser products shall not cause damage to the eyes or unintended damage to the skin in case of any exposure to laser radiation that could occur under normal or reasonably foreseeable conditions of use, including momentary accidental or unintentional exposure.

In short this requires any laser or laser product that can be purchased or used by a consumer to be Class 1 or Class 2.

Souce: Europa.eu, Europa.eu, EN-50689:2021, EN-60825-1:2014

4 quick questions to verify a Class 1 laser product.

01

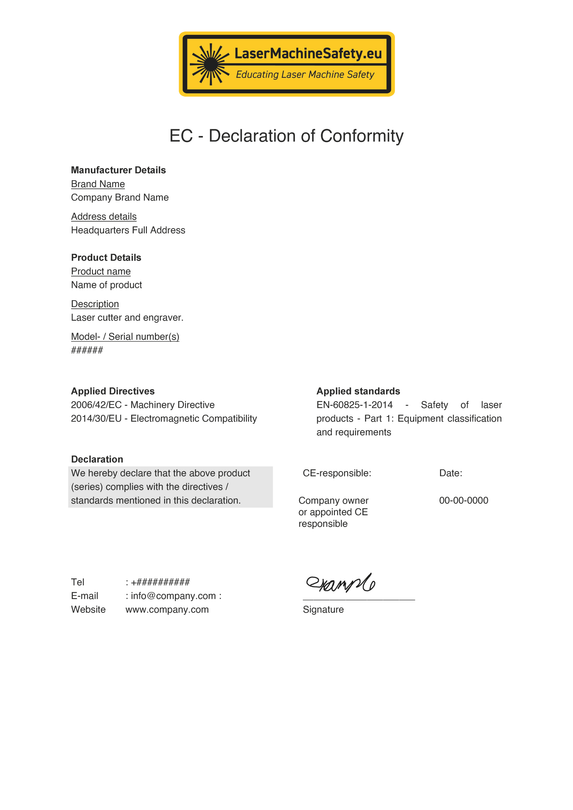

EC-Declaration?

Can the company deliver a EC/EU-declaration with the appropriate Directives/standards?

This is a legal requirement for any machinery sold in europe.

02

Do you need to access the laser?

A true Class 1 laser will never expose you to hazardous levels of laser radiation.

This includes maintenance but may exclude service.

03

Two channel interlocks?

Does the machine have 2 single channel or 1 dual channel interlock/s?

One simple door sensor/interlock is never safe for a laser cutter. Two interlock channels are required to ensure the laser will not operate if a singular sensor fails.

04

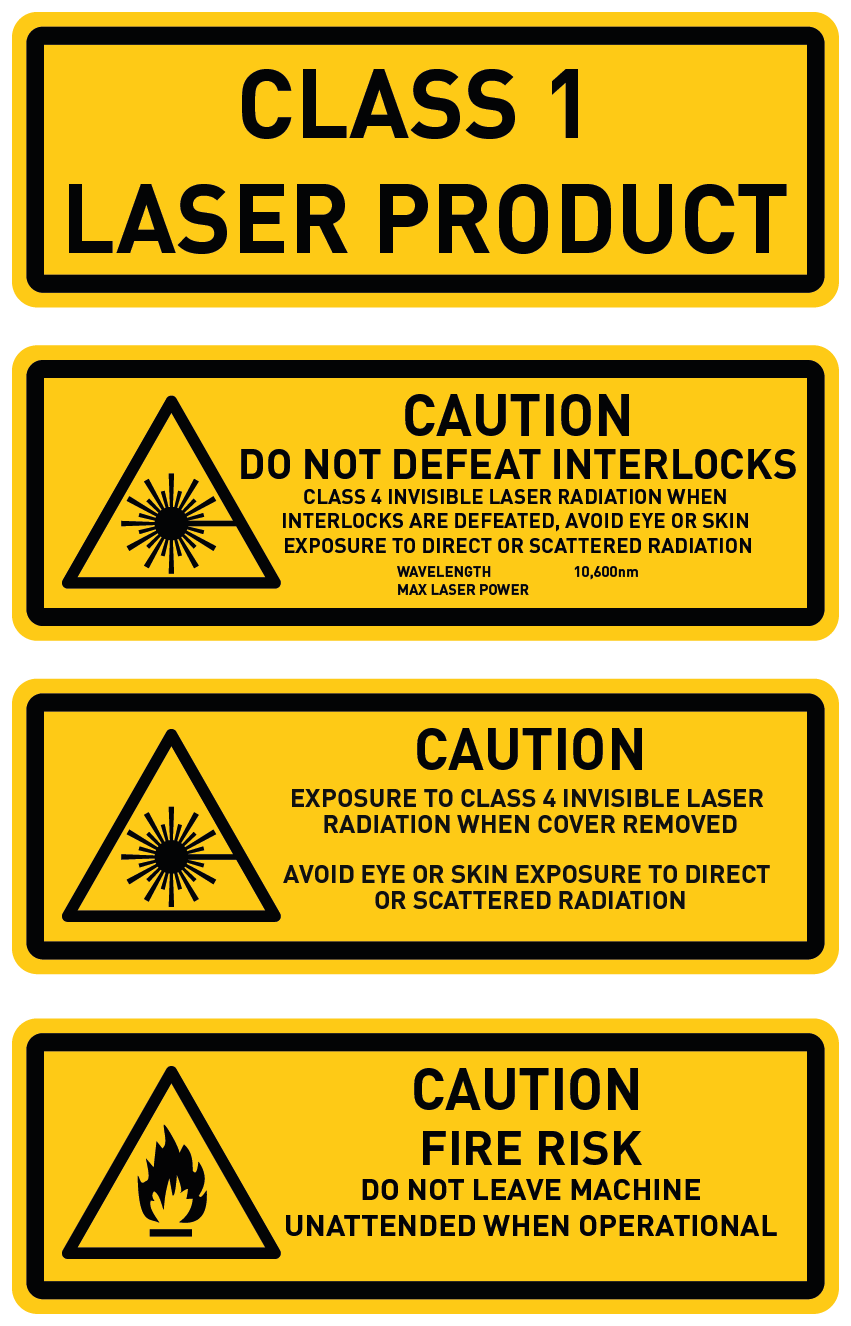

Are there warning stickers?

Inside every laser cutter designed for cutting materials will be a powerful Class 4 laser.

Should you remove panels, defeat interlocks or have a catastrophic failure, you may be exposed to Class 4 laser radiation.

Therefore it is important your machine has the proper warning labels.

*This is not an exhaustive list, but a good indicator the machine you are considering is indeed a Class 1 laser product.

Laser Classification

| Classification EN60825-1* | Description |

|---|---|

| Class 1 | Laser product is safe during all foreseeable use. Suitable for everyone; home, schools, fablabs, etc |

| Class 2 | Laser product may cause harm but is very low risk due to blink reflex. Do not deliberately stare into the beam for longer than 0.25s. Suitable for everyone; home, schools, fablabs, etc |

| Class 3R | Laser product is unsafe should you accidentally stare into the beam. Only suitable for businesses with specifically trained personal. |

| Class 3B | Laser product is unsafe, high risk of permanent eye damage and burning of skin. Only suitable for businesses with specifically trained personal with PPE. |

| Class 4 | Laser product is unsafe, high risk of permanent eye damage and burning of skin. Only suitable for businesses with specifically trained personal with PPE. |

*Summarised from EN60825-1:2014, some classifications have been omitted due to irrelevance in regards to laser processing machines.

Is a Laser Cutter a Machine?

Yes. If it is intended to burn, engrave and/or cut material through the use of motorized CNC equipment it is subject to the Machine Directive.

Baua, the Federal Institute for Occupational Safety and Health has created a comprehensive overview for the public.

Souce: Baua.de

(Some of ) The Requirements for a Safe Laser Product

Machinery Directive (MD) 2006/42/EC

One of the main legislations governing essential health and safety requirements for machinery at EU level.

This document explains the basic requirements for machinery sold in the EU, and is required to be able to apply CE to a machine.

EN-ISO-11553-1:2020

Safety of machinery - Laser processing machines - Part 1: laser safety requirements.

This document explains to a manufacturer all the requirements in building a Safe laser processing machine.

EN-60825-1: 2014

Safety of laser products - Part 1: Equipment classification and requirements.

This talks about how to classify a laser or laser product. When a manufacturer states a laser classification, this is the standard that must be adhered to.

EN-60825-4: 2006

Safety of laser products - Part 4: Laser guards.

This document explains how to build a safe machine enclosure and requirements about how long before the laser may burn through the enclosure.

EN-ISO-14119: 2013

Safety of Machinery - Interlocking devices associated with guards- principles for design and selection.

This document explains the requirements for the physical interlocks on the machine.

EN-ISO-13849-1: 2015

Safety of machinery - Safety-related parts of control systems - part 1: General principles for design.

This document explains the requirements for the safety control system; how to ensure the machine can always be operated safely.

OK, I am not going to read all of those documents, what safety things do I actually want to look for?

CE Mark / Certification

A CE certified laser cutter will always have a CE mark attached to it. This CE mark must be that of European Conformance (Not China Export/Incorrect CE marking).

This mark should indicate that the most basic parts of the machine are safe, built following the European Machinery directive. If the incorrect logo is placed, the machine does not conform to the European Machinery directive and may not be sold or used.

Buying such a machine puts you at personal risk that if the machine is checked by a health and safety officer, it may no longer be used. Many imported machines carry 'Fake' CE/China Export symbol, which you must be wary of.

Source:

Europa.eu,

CEMarking.net,

EU Declaration Of Conformity

A CE Mark on the machine is only half the story. The EC Declaration, sometimes referred to as CE declaration, EU Declaration or DoC, is a declaration of what your machine conforms to, and must be supplied with your machine. Otherwise it is impossible to know to what standards and directives the product is certified to.

This document is often placed in the manual but may be supplied separately. It is mandatory to deliver a EU declaration of conformity with your machine.

On the right is an example EC Declaration of conformity. A document with similar information to this example is a legal requirement for machines sold in the EU.

If the supplier cannot supply this simple document one may wonder what else the machine will be lacking?

Source: Europa.eu, Machine Directive

What Features to look for?

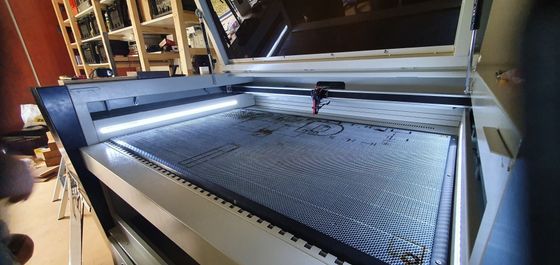

Machine Enclosure

Open laser cutters which have no enclosure are not safe and should not be used by consumers or schools.

An example from RAPEX banning the sale of an open diode laser cutter/engraver system in the EU.

Source: Rapex

A Class 1 or 2 laser cutter must fully enclose the laser.

The machine needs to be made from laser safe materials. According to

EN-60825-1:2014, a Class 1 laser enclosure needs to be able to withstand the direct exposure to the embedded laser under all foreseeable circumstances.

This means your enclosure needs to prevent burn through in areas all the laser could be expected to make contact with during general operation, but also during foreseeable single fault failure, for 30,000s (8hours).

Due to this requirement, the body of the machine should in most cases be made of metal, such as steel or aluminium.

All parts, including the door of the machine should be able to withstand whatever power the laser may accidentally hit it with.

For example, in a case of accidental misalignment, the door as well as the frame must be able to withstand the full power of the beam, for the full duration of 8 hours.

Alternatively the beam may be well constrained or other engineering methods may be used such that foreseeable misalignment is not considered a single fault.

Many machines have a door made of acrylic, which although absorbs stray reflections, will often quickly burn through if it is hit by the direct laser beam.

Acrylic is only an acceptable material if the laser beam path is constrained such that only reflections are expected to hit the door.

According to EN-60825-4:2006, polycarbonate is the preferred material over acrylic, when transparency is required, for protecting against CO2 lasers.

In short, if the door is made of acrylic and is in line with the optical path, it is likely not safe.

Interlocks

All panels that you need to access for operation or maintenance need to be safely (and redundantly) interlocked. This includes all panels required for cleaning or aligning the mirrors.

An interlock should be fail-safe, meaning it should not be possible to override with for example a singular magnet or piece of metal as this could happen accidentally.

According to 14119:2013 Safety of Machinery - Interlocking devices associated with guards- principles for design and selection, if a non-contact interlock device - such as a magnet, is the only interlock device, it must meet the requirements of IEC 60947-5-3.

In short, a singular sensor is never sufficient as a interlocking system for a laser cutter.

Additionally, any non-interlocked panels must be affixed with screws or locked with a certified key, and are only to be used for service. This means you should never need to access this area of the machine when it is on, and should only ever access this area for critical repairs (Not maintenance). These panels must not be able to be placed back without either returning the screws or locking them.

If these safety systems are not in place, the machine is not safe to be classified as a Class 1 laser according to EN-IEC 60825-1:2014 Safety of laser products - Part 1: Equipment classification and requirements.

A simple switch does not encapsulate a laser

An example from RAPEX banning the sale of a CO2 laser cutter with an enclosure but improperly interlocked rendering the machine essentially open and unsafe.

Source: Rapex

Safety Control System

Having interlock redundancy is only half the story.

What system insures these interlocks are functional?

What system ensures that when the door opens, the laser shuts down?

As a laser cutter can cause irreversible damage, even though the chance may be low, it is considered a very high risk.

As dictated in EN-ISO-11553-1:2020, performance level of d (Pld) must be achieved to standard EN-ISO-13849-1:2015.

This is commonly achieved through the use of off the shelf safety relays. However, it is also possible for the manufacturer to develop an integrated system.

These are just examples, the text and design may vary depending on the laser product.

Machine Stickers

Warning stickers on the machine may seem unnecessary, as a Class 1 laser is always safe. However, even though you are buying a Class 1 laser product, there is still a Class 4 laser inside which could, when the machine is not operated correctly, lead to dangerous situations.

According to EN 60825-1, laser products are only exempt from labelling requirements if the manufacturer proves that the product does not exceed the AEL of Class 1 under all conditions of operation, maintenance, service and foreseeable failure.

If it is possible for a determined user to override safety systems to gain access to Class 4 radiation, or through the removal of (screwed on) service panels, the machine is not

except from labelling requirements.

There are a few different stickers and labels you should look for, as shown on the left.

Laser warning stickers must warn the user of the laser inside, and inform them of what power levels there are. With a CO2 laser, the laser warning stickers must use the phrasing “Invisible laser radiation” to warn you that the beam cannot be seen.

Laser cutters should also have a warning sticker about Fire Risks. Lasers use a high energy beam to cut the materials. This process has a risk of causing a fire.

Source: EN-60825-1: 2014

Restricting Access

Will the machine be placed in a locked room or will it be freely accessible for people to use?

Although not required for a Class 1 laser, some Class 1 machines come with key switches to ensure the laser can only be used by authorised personnel, or for example when students are under supervision. Even though the machine in principle is safe, it is best to ensure it can only be used by those who have read the safety instructions.

Hungry for More Topics and Knowledge?

Check out our Knowlage base where we explore more laser machine safety topics and concerns.